Technicial Specifications

| Engine Power - ISO 14396:2002 | 580 hp 432 kW |

| Engine Model | Cat® C18 Cat® C18 |

| Rated Speed | 1700/rpm 1700/rpm |

| Peak Power Speed | 1500/rpm 1500/rpm |

| Gross Power - SAE J1995:2014 | 588 hp 439 kW |

| Net Power - SAE J1349:2011 | 538 hp 401 kW |

| Bore | 5.7 in 145 mm |

| Stroke | 7.2 in 183 mm |

| Displacement | 1105 in³ 18.1 l |

| Peak Torque - 1,200 rpm | 2104 lbf·ft 2852 N·m |

| Torque Rise | 58 % 58 % |

| Note (1) | Three engine emission options are available: 1. Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards. 2. Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA. 3. Meets China Nonroad Stage IV emission standards. Three engine emission options are available: 1. Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards. 2. Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA. 3. Meets China Nonroad Stage IV emission standards. |

| Note (2) | Net power advertised is the power available at the flywheel when the engine is equipped with fan at minimum speed, air intake system, exhaust system, and alternator. Net power advertised is the power available at the flywheel when the engine is equipped with fan at minimum speed, air intake system, exhaust system, and alternator. |

| Operating Weight | 112574 lb 51062 kg |

| Bucket Capacity Range | 4.7-13 m3 (6.2-17 yd3) 4.7-13 m3 (6.2-17 yd3) |

| Rated Payload - Quarry Face | 12.5 t 11.3 t |

| Rated Payload - Loose Material | 16 t 14.5 t |

| Cat Truck Match - Standard | 770 - 772 770 - 772 |

| Cat Truck Match - High Lift | 773 - 775 773 - 775 |

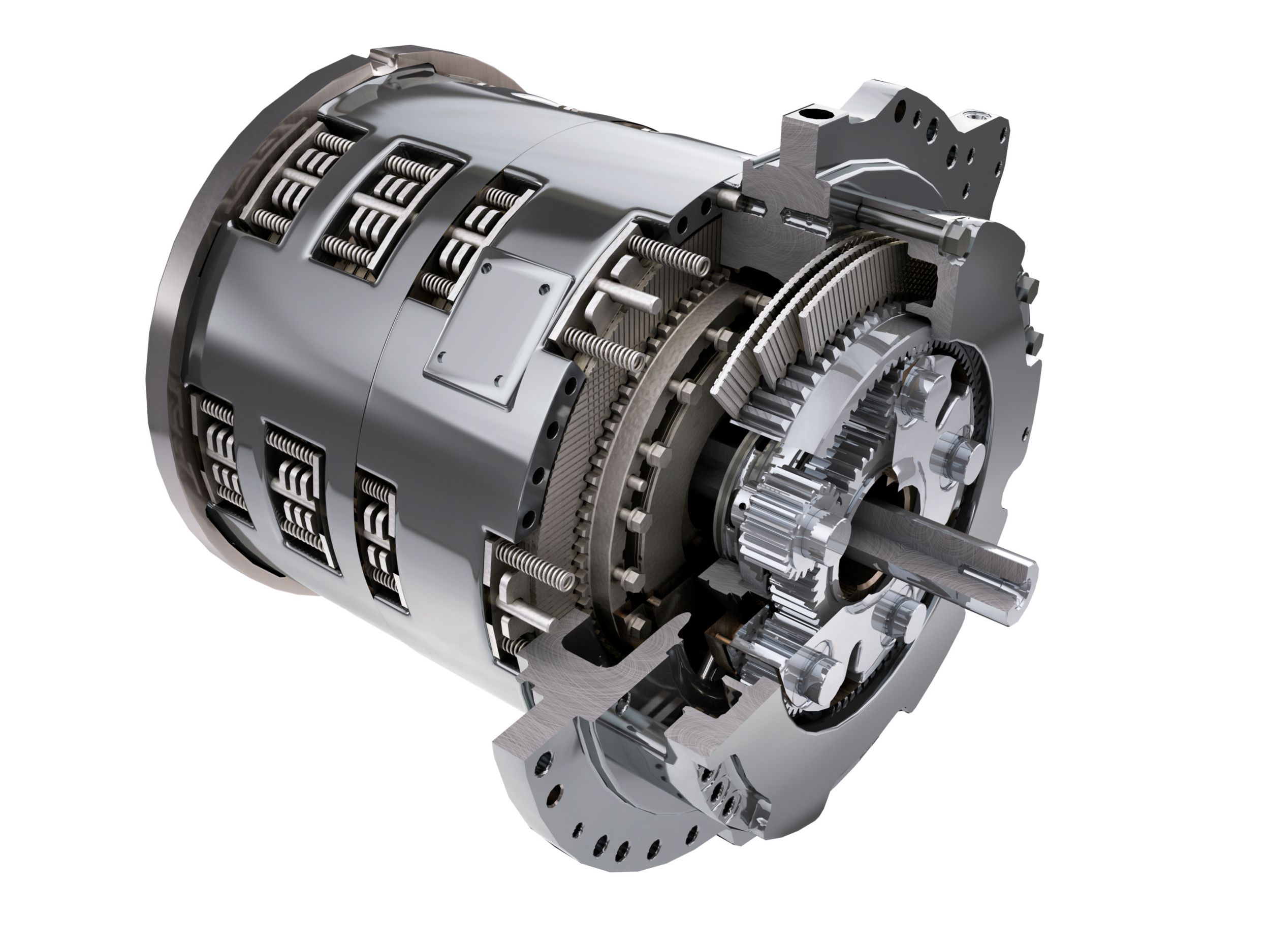

| Transmission Type | Cat planetary powershift Cat planetary powershift |

| Forward - 1 | 4 mile/h 6.5 km/h |

| Forward - 2 | 7.2 mile/h 11.6 km/h |

| Forward - 3 | 12.7 mile/h 20.4 km/h |

| Forward - 4 | 21.6 mile/h 34.7 km/h |

| Reverse - 1 | 4.7 mile/h 7.5 km/h |

| Reverse - 2 | 8.3 mile/h 13.3 km/h |

| Reverse - 3 | 14.4 mile/h 23.2 km/h |

| Direct Drive - Forward 1 | Lock-up disabled Lock-up disabled |

| Direct Drive - Forward 2 | 7.8 mile/h 12.5 km/h |

| Direct Drive - Forward 3 | 13.9 mile/h 22.3 km/h |

| Direct Drive - Forward 4 | 24.4 mile/h 39.3 km/h |

| Direct Drive - Reverse 1 | 5 mile/h 8 km/h |

| Direct Drive - Reverse 2 | 8.9 mile/h 14.3 km/h |

| Direct Drive - Reverse 3 | 15.8 mile/h 25.5 km/h |

| Lift/Tilt System - Circuit | EH- Positive Flow Control, Flow Sharing EH- Positive Flow Control, Flow Sharing |

| Lift/Tilt System - Pump | Variable displacement piston Variable displacement piston |

| Maximum Flow at 1,400-1,860 rpm | 153 gpm 580 L/min |

| Relief Valve Setting - Lift/Tilt | 4757 psi 32800 kPa |

| Cylinders, Double Acting - Lift, Bore and Stroke | 210 mm × 1050 mm (8.7 in × 41.3 in) 210 mm × 1050 mm (8.7 in × 41.3 in) |

| Cylinders, Double Acting - Tilt, Bore and Stroke | 266 mm × 685 mm (8.7 in × 27 in) 266 mm × 685 mm (8.7 in × 27 in) |

| Pilot System | Variable displacement piston Variable displacement piston |

| Relief Valve Setting - Main | 551 psi 3800 kPa |

| Rack Back | 4.5 s 4.5 s |

| Raise | 8 s 8 s |

| Dump | 2.2 s 2.2 s |

| Lower Float Down | 3.5 s 3.5 s |

| Total Hydraulic Cycle Time - Empty Bucket | 18.2 s 18.2 s |

| Steering System - Circuit | Pilot, load sensing Pilot, load sensing |

| Steering System - Pump | Piston, variable displacement Piston, variable displacement |

| Maximum Flow at 1,400-1,600 rpm | 71.3 gpm 270 L/min |

| Relief Valve Setting - Steering | 4351 psi 30000 kPa |

| Total Steering Angle | 86 ° 86 ° |

| Steering Cycle Times - High Idle | 3.4 s 3.4 s |

| Steering Cycle Times - Low Idle | 5.6 s 5.6 s |

| Air Conditioning | • The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. • If equipped with R134a (Global Warming Potential = 1430), the system contains 1.8 kg (3.9 lb) of refrigerant which has a CO2 equivalent of 2.574 metric tonnes (2.837 tons). • The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. • If equipped with R134a (Global Warming Potential = 1430), the system contains 1.8 kg (3.9 lb) of refrigerant which has a CO2 equivalent of 2.574 metric tonnes (2.837 tons). |

| Front | Fixed Fixed |

| Rear | Trunnion Trunnion |

| Oscillation Angle | 13 ° 13 ° |

| Brakes | ISO 3450:2011 ISO 3450:2011 |

| ROPS/FOPS | ROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards ROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards |

| Operator Sound Pressure Level (ISO 6396:2008) | 73 dB(A) 73 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 111 dB(A) 111 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 72 dB(A) 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)** | 109 dB(A) 109 dB(A) |

| Note (1) | * For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.” * For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.” |

| Note (2) | ** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701. ** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701. |

| Note (3) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (4) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (5) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Operator Sound Pressure Level (ISO 6396:2008) | 73 dB(A) 73 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 112 dB(A) 112 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 72 dB(A) 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)** | 110 dB(A) 110 dB(A) |

| Note (1) | * For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.” * For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.” |

| Note (2) | ** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701. ** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701. |

| Note (3) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (4) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (5) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Fuel Tank | 188 gal (US) 712 l |

| Cooling System | 31.7 gal (US) 120 l |

| Coolant (Validated by Test Cell Fill Quantities) | 33 gal (US) 125 l |

| Crankcase | 15.9 gal (US) 60 l |

| Diesel Exhaust Fluid Tank (For Tier 4 Final/Stage V Only) | 8.7 gal (US) 33 l |

| Transmission | 24.3 gal (US) 92 l |

| Transmission - Validated by Test Cell Fill Quantities | 29 gal (US) 110 l |

| Differential - Final Drives - Front | 49.1 gal (US) 186 l |

| Differential - Final Drives - Rear | 49.1 gal (US) 186 l |

| Hydraulic System Factory Fill | 125.5 gal (US) 475 l |

| Hydraulic System - Tank Only | 63.4 gal (US) 240 l |

| Note | • All non-road Tier 4 Final/Stage V diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: – 20% biodiesel FAME (fatty acid methyl ester)* – 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. • Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).** • For pre-Tier 4 engines: Cat engines are compatible with diesel fuel blended with the following lower-carbon intensity fuels** up to: – 100% biodiesel FAME (fatty acid methyl ester)* – 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * For use of blends higher than 20% biodiesel, consult your Cat dealer. ** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. • All non-road Tier 4 Final/Stage V diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: – 20% biodiesel FAME (fatty acid methyl ester)* – 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. • Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).** • For pre-Tier 4 engines: Cat engines are compatible with diesel fuel blended with the following lower-carbon intensity fuels** up to: – 100% biodiesel FAME (fatty acid methyl ester)* – 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * For use of blends higher than 20% biodiesel, consult your Cat dealer. ** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. |

| Ground to Top of ROPS | 13.8 ft 4202 mm |

| Ground to Top of Exhaust Stacks | 14.8 ft 4521 mm |

| Ground to Top of Hood | 10.9 ft 3334 mm |

| Rear Axle - Centerline to Bumper | 10.5 ft 3187 mm |

| Front Axle Centerline to Bucket Tip | 14 ft 4254 mm |

| Wheel Base | 14.9 ft 4550 mm |

| Maximum Overall Length | 39.3 ft 11991 mm |

| Ground to Lower Hitch Clearance | 1.9 ft 568 mm |

| Clearance at Maximum Lift | 11.9 ft 3641 mm |

| B-Pin Height - Maximum Lift | 18 ft 5485 mm |

| Maximum Overall Height - Bucket Raised | 24.5 ft 7455 mm |

| Reach - Maximum Lift | 6.5 ft 1981 mm |

| Ground to Top of ROPS | 13.8 ft 4202 mm |

| Ground to Top of Exhaust Stacks | 14.8 ft 4521 mm |

| Ground to Top of Hood | 10.9 ft 3334 mm |

| Rear Axle - Centerline to Bumper | 10.5 ft 3187 mm |

| Front Axle Centerline to Bucket Tip | 15.3 ft 4661 mm |

| Wheel Base | 14.9 ft 4550 mm |

| Maximum Overall Length | 40.7 ft 12398 mm |

| Ground to Lower Hitch Clearance | 1.9 ft 568 mm |

| Clearance at Maximum Lift | 13.3 ft 4043 mm |

| B-Pin Height - Maximum Lift | 19.3 ft 5887 mm |

| Maximum Overall Height - Bucket Raised | 25.8 ft 7849 mm |

| Reach - Maximum Lift | 6.8 ft 2062 mm |

Advantages and Features

PROVEN RELIABILITY

- Cat C18 engine is built and tested to meet your most demanding applications.

- Cat torque converter with lock-up clutch helps reduce torque converter losses and lowers system heat.

- Maximum responsiveness with Steering and Transmission Integrated Control (STIC™).

- Moves more material efficiently with improved power and control.

- Durable construction withstands the toughest loading conditions and multiple lifecycles.

LONG TERM VALUE AND DURABILITY

- World-class transmission for long life and consistent, smooth shifting; specifically designed for mining applications.

- Advanced productivity electronic control strategy (APECS) transmission controls for optimal momentum on grades.

- Positive flow control (PFC) hydraulic system helps increase efficiency, bucket feel, and responsiveness with consistent performance.

- Advanced filtration system for extended performance and reliability of the hydraulic system.

- Impeller clutch torque converter (ICTC) helps minimize tire spin by allowing torque to adjust to underfoot conditions.

PERFORMANCE AND PRODUCTIVITY

- Superior digging, higher bucket fill factors, reduced dig times.

- Improved visibility over the top of the linkage.

- Operators can now monitor tire pressure during operation. Any change sending a fault code to VisionLink®, helps prevent premature tire failure.

- Convenient, responsive, electro-hydraulic controls help increase operator productivity.

PERFORMANCE WITH LESS FUEL

- Economy mode helps optimize engine speed control for reduced fuel consumption no matter if operating in manual throttle or throttle lock.

- Flow sharing hydraulics provide full flow at reduced engine rpm.

- Fully integrated electronic engine controls help make your fuel go farther.

- Engine idle shutdown for less fuel used while idling.

- Increased hydraulic speed and fast cycle times helps decrease idle and fuel burn, with optimal efficiency.

PRODUCTIVITY WITH TECHNOLOGY

- Cat Technologies developed to monitor, manage, and enhance your jobsite operations.

- Cat Payload provides accurate weighing* of the materials you are loading and hauling. Payload data is displayed in real-time to improve productivity and reduce overloading.

- Cat Detect enhances awareness of the environment around working equipment and provides alerts to help keep people and assets safe on the jobsite.

- Product Link™ wirelessly connects you to your equipment, giving you access to essential information you need to know to run your business.

- Gain valuable insight into how your machine or fleet is performing.

- Optional advanced productivity plan provides comprehensive actionable information to help you manage and improve the productivity and profitability of your operations.

- Improved cycle times and bucket fill factors with optional operator coaching.

- Optimized dig segment cycle with optional operator assist – tire slip prevention, auto set tires, and lift stall prevention.

- Easy to operate in single pedal with dynamic braking and operator assist features that allow faster training of new operators.

- Increase operator efficiency with Operator Coaching through onboard tips for truck loading operations.

SAFETY FIRST

- Achieve precise positioning for easy loading in tight areas with 43 degrees of steering articulation.

- Precise machine control by load-sensing hydraulic steering system.

- Reduced stairway angles and standard stairway lighting provide reduced risk of slips, trips, and falls due to better visbility of the steps and stairway.

- Computerized monitoring system with warning indicators.

- Standard Cat Vision enhances visibility behind the machine, helping you work safely and confidently.

- Pressurized cabin with filtered air and reduced sound levels.

SAVE ON SERVICE AND MAINTENANCE

- Grouped service points provide easy access to critical daily service checks.

- Swing-out engine compartment service doors.

- Reduced waste with maintenance-free batteries.

- Ecology drains to prevent spills and allow for easier service.

- Vehicle Information Management System (VIMS™) notifications to help resolve problems before failure.

- Ground level access to transmission control valves.

- Long life, rebuildability, and high resale value.

OPERATOR COMFORT AND CONTROL

- World-class operator comfort and ergonomics.

- Cat Premium Plus seat with standard features including leather finish, forced air heating and cooling, two-way thigh adjustment, power lumbar and back bolster adjustment, and dynamic end dampening to provide total comfort throughout the workday.

- Easy-to-reach levers and seat-mounted implement pod to help reduce fatigue.

- Ergonomic switch placement and displays with LED indicators.

- Two-position rocker switch activates the electro-hydraulic parking brake.

- Reduced vibrations from isolated cab mounts and seat air suspension.

- Automatic cab temperature controls.

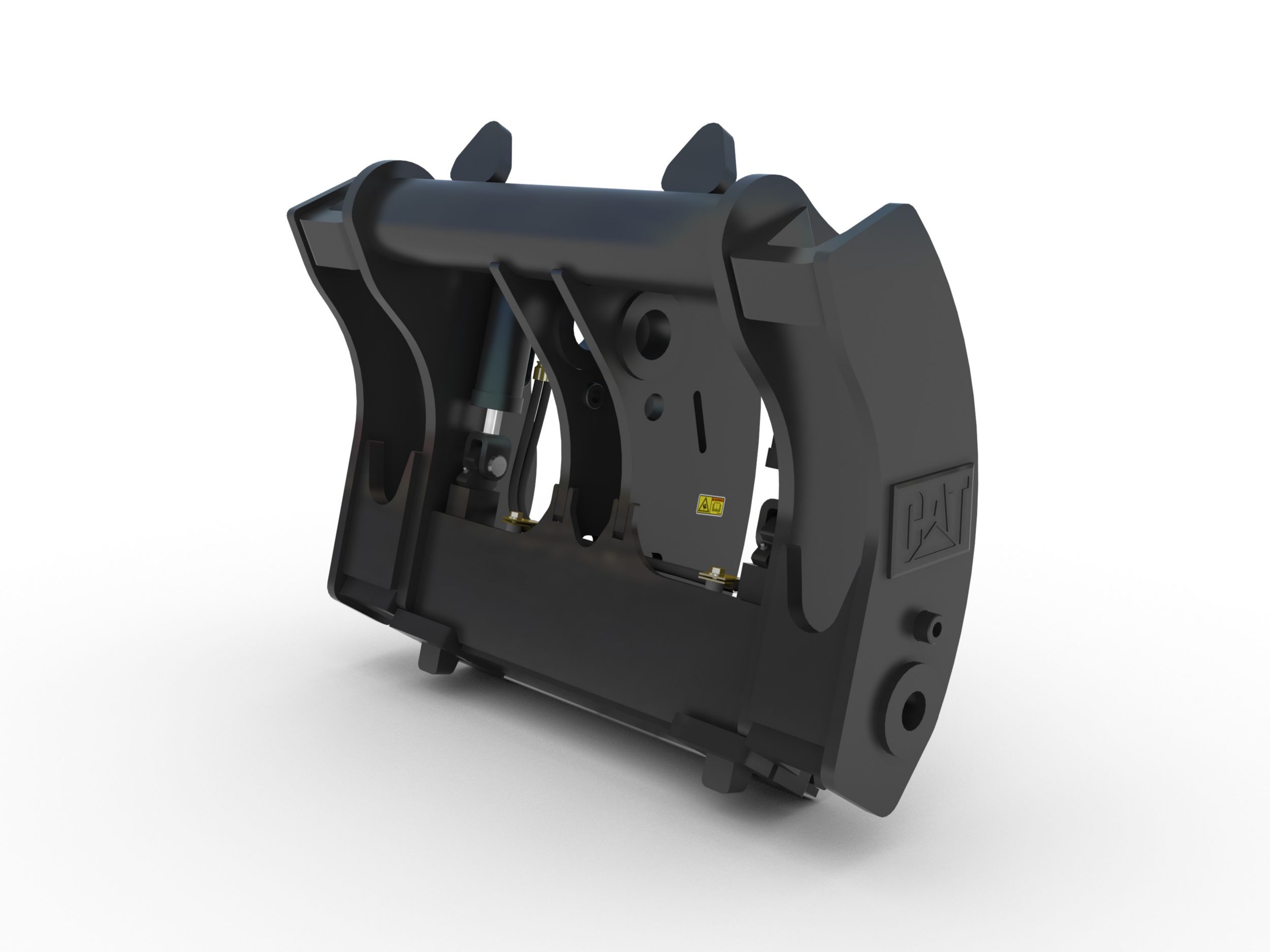

PURPOSE-BUILT SPECIALTY MODELS - BLOCK HANDLER

- Delivers stability and durability with an optimized counterweight for block handling applications.

- A high rimpull powertrain features a torque converter and transmission specially designed for this application to maximize rimpull.

- An additional hydraulic valve with the quick coupler allows the operator to switch work tools and immediately lock the work tool during load and carry applications.

- Purpose-built tilt and lift cylinders on the linkage help improve load control and ensure safe and long lasting operation.

- Ride control acts as a shock absorber, providing the operator with a smoother ride over rough terrain.

PURPOSE-BUILT SPECIALTY MODELS - MILLYARD

- Unload a typical full-length log truck in a single pass with the larger lift and tilt cylinders and a unique tilt lever to maximize linkage force. Designed with more lift capacity and 26% more tilt capacity over the standard 988.

- Swing out fan radiator design for easy service in high-debris millyard applications helping to reduce maintenance and service down time. Auto reversing fan system to help dislodge debris and keep air flowing across the radiator cores.

- Additional counterweight to help increase stability for improved confidence while maneuvering with full loads.

- Purpose-built lift arm with lowered cross member to help increase visibility to the tips of the forks helping to increase the speed when lining up the load and reduce operator movements to see the forks.

PURPOSE-BUILT SPECIALTY MODELS - STEEL MILL

- Durable and reinforced attachments for operator comfort, safety, and easy machine access.

- Radiator is designed for easy cleaning and to keep material from building up.

- Auto reversing fan and easy access to cooling cores help keep cab at comfortable temperature.

- Equipped with extra guarding and heat protection for critical machine functions.

- Flame resistant ecosafe hydraulic fluid available as an option.

- Performance series, serrated edge slag, straight edge slag, and slag buckets help maximize material retention and minimize dig time.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

ELECTRICAL

- Alarm, back-up

- Alternator, single 150 amp

- Batteries, dry

- Converter, 10/15 amp, 24V to 12V

- Lighting system (LED, work lights, access and service platform lighting)

- Starting and charging system, 24V

- Auxiliary jump start receptacle

- Starter lockout in bumper

- Transmission lockout in bumper

-

OPERATOR ENVIRONMENT

- Graphical Information Display, displays real time operating information, performs calibrations and customizes operator settings

- CB radio ready

- Air conditioner

- Cat Vision, rear vision camera system

- Cab, sound suppressed and pressurized, integrated rollover protective structure/falling objects protective structure (ROPS/FOPS) radio ready for entertainment, includes antenna, speakers and converter (12-volt 5-amp) and power port

- Controls, lift and tilt function

- Heater, defroster

- Horn, electric

- Instrumentation, gauges: – Coolant temperature – Engine hour meter – Hydraulic oil temperature – Powertrain oil temperature

- Light, cab, dome

- Lunchbox, beverage holders

- Radio, AM/FM/CD/MP3 Bluetooth®

- Mirrors, rearview (externally mounted)

- Rimpull Control System (RCS)

- Seat, deluxe

- Seat belt minder

- Seat belt, retractable, 76 mm (3 in) wide

- Steering and Transmission Integrated Control (STIC™) System

- UV glass

- Vital Information Management System (VIMS™) with Graphical Information Display: External Data Port

- Wet-arm wipers/washers (front and rear): – Intermittent front and rear wipers

- Lights, directional

-

POWERTRAIN

- Brakes, oil-cooled, multi-disc, service/secondary

- Case drain screens

- Electro hydraulic parking brake

- Engine, C18 Mechanically Actuated Electronic Unit Injection (MEUI™) diesel, turbocharged/aftercooled

- Ground level engine shutdown switch

- Turbine precleaner, engine air intake

- Premixed 50% concentration of extended life coolant with freeze protection to –34° C (–29° F)

- Radiator, Aluminum Modular Radiator (AMR)

- Starting aid, ether, automatic

- Throttle lock, electronic

- Torque converter, Impeller Clutch (ICTC) with Lock up clutch (LUC), Rimpull Control System

- Transmission, planetary powershift, 4F/3R electronic control

- Manual switch and automatic fuel priming

- Cat Production Measurement ready

-

ADDITIONAL EQUIPMENT

- Base machine price includes a rim allowance

- Hydraulically driven demand fan

- Couplings, Cat O-ring face seals

- Doors, service access (locking)

- Ecology drains for engine, radiator, hydraulic tank

- Fuel tank, 712 L (188 gal)

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Hydraulic, steering and brake filtration/screening system

- Cat Clean Emission Module (CEM)

- Oil sampling valves

- Rear access to cab and service platform

- Steering, load sensing

- Toe kicks

- Vandalism protection caplocks

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWERTRAIN

- –50° C (–58° F) antifreeze

- Crankcase guard

- Engine oil change system, high speed, Wiggins

- High ambient cooling – software

- Cat Production Measurement

-

OPERATOR ENVIRONMENT

- Cab precleaner

- LED warning strobe

- Window pull down visor

- Handrail mounted mirrors

-

ADDITIONAL EQUIPMENT

- Additional counterweight

- Front and rear roading fenders

- Fast fill fuel system (Shaw-Aero)

- Cold weather package: additional starter and 2 batteries, engine block heater 120V or 240V, heated fuel lines

-

OTHER OPTIONAL CONFIGURATIONS

- Aggregate Handler

- Block Handler

- Millyard

- Steel Mill